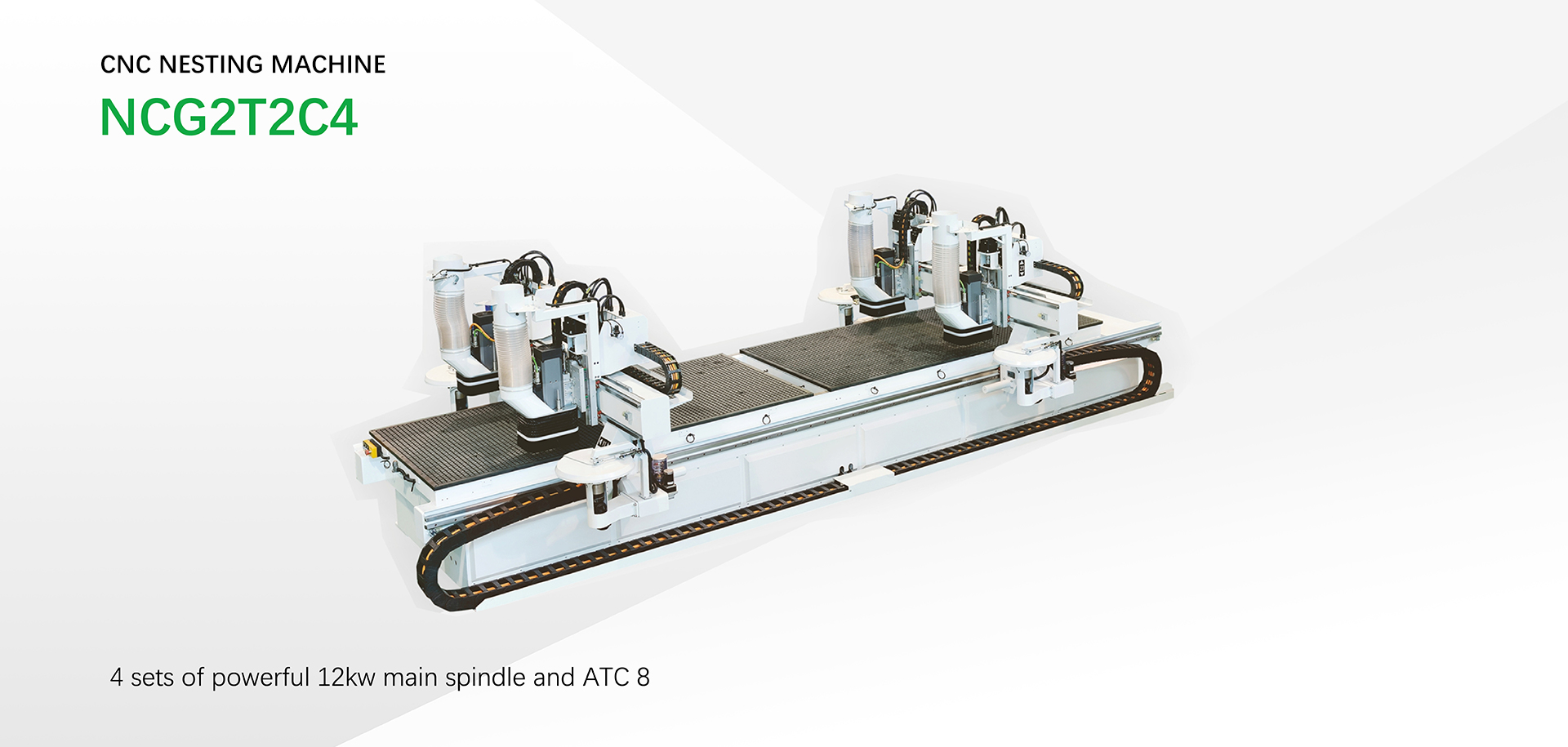

NCG2T2C4 is specially designed for cutting, flexible and high efficient for customized production due to 4 sets of powerful 12kw main spindle and ATC 8 working on two gantries and 2 working area, , this is ideal machine to combine with robots to build cutting working cell

+357 77 770629

+357 77 770629

| Model | NCG2812E |

|---|---|

| Table size | 2800×1230mm |

| Max speed | 80/80/20 m/min |

| Main spindle power | 12kw X4 |

| Max rotating speed | 24000rpm |

| Vertical Drills | 8x4 |

| Vacuum pump | 7.5kw |

| Suction flow rate | 250m3/h |

| Dust extraction | φ200mm×4 |

| Total power | 88kw x2 |

| Overall dimension | 6520×2600×2500mm |

| Net weight | 4750kg |