+357 77 770629

+357 77 770629

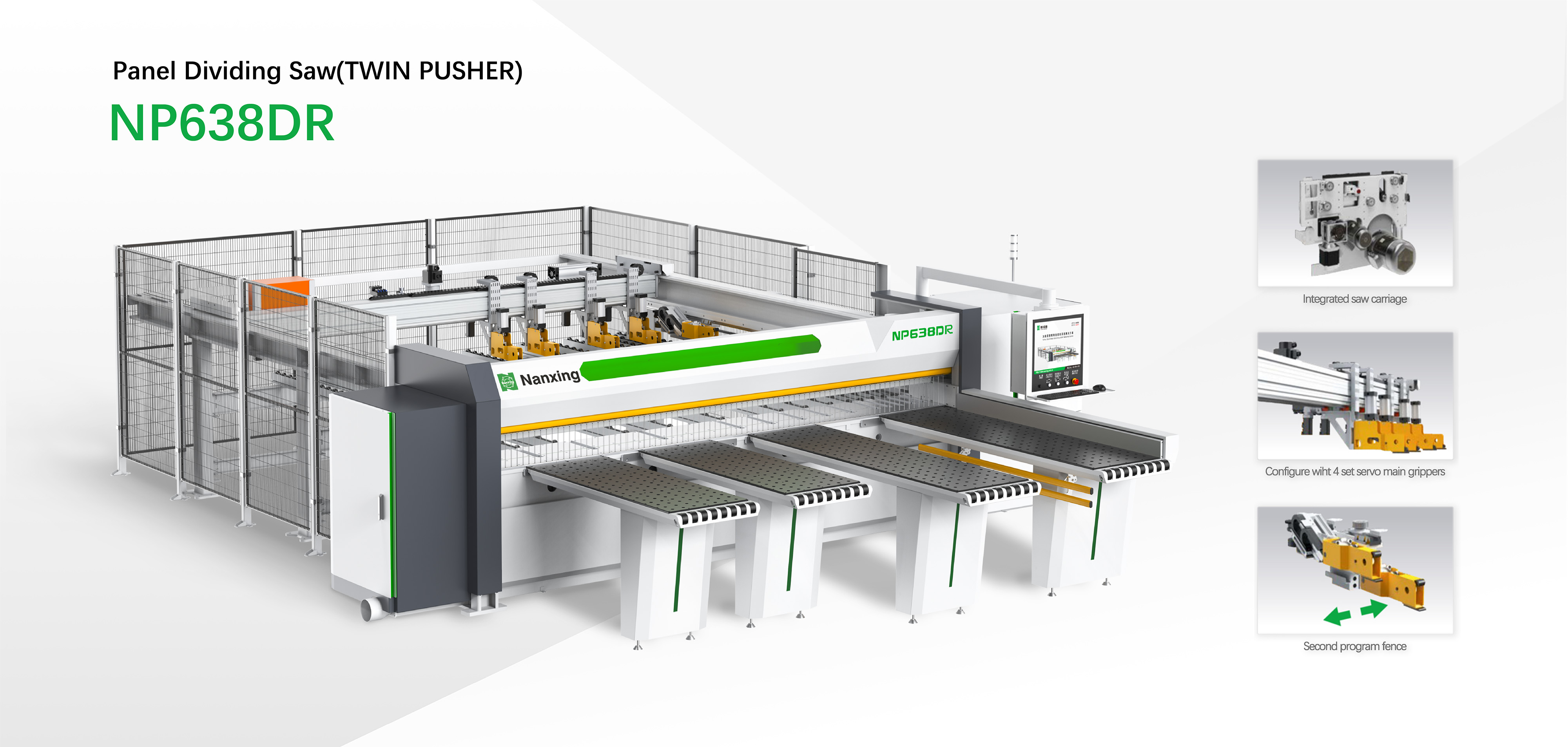

| Model | NP638DR |

|---|---|

| Cutting | Max. cutting length 3,800mm Max.cutting thickness 90mm |

| Main saw | Motor power 15kw Rotating speed 3,910rpm/min Saw blade diameter 380mm(max400) Saw blade shaft diameter 60mm |

| Scoring saw | Motor power 2.2kw Rotating speed 4,300rpm/min |

| Saw carriage | Motor power 2kw Forward speed 90m/min Backward speed 120m/min |

| Feeding | Automatic feeding motor 2kw Main grippers:85m/min Scoring grippers:55m/min |

| Gripper qty | 2+4 pcs |

| Blower | 2kw |

| Air Requirement | 0.6 MPa |

| Dust extractione | 150mm*3 28m/min |

| Power supply | AC3P380V/50Hz |

| Total power | 26kw |

| Overall size | 7.500 x6,000 x1,820mm |

| Net weight | 6,500kg |